MIKRON VCE800 PRO

mitsubishi ba24

Wire EDM machine with working range X = 600 Y = 400 cutting height 250 mm. Equipped with new generation technologies that guarantee excellent performance especially in hard metal machining.

MIKRON VCE800 PRO

Wire EDM machine with working range X = 600 Y = 400 cutting height 250 mm. Equipped with new generation technologies that guarantee excellent performance especially in hard metal machining.

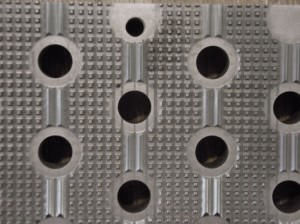

MITSUBISHI MP2400

With a wire diameter of 0.05 mm even in standard conditions, it performs braze welding to ensure scrap holding and a fully heat-stabilised structure that, together with the super finisher of the new electric generator, can achieve dimensional accuracies from 0.001 mm to 0.002 mm with a roughness of Ra 0.08.

mitsubishi EA8S

MITSUBISHI EA8S die-sinking EDM with 10-slot electrode changer for optimised production times.